V1K Motor Protection Filter

TMS & TCI for over 16 years the difference in service and power quality solutions for the canadian market.

V1K Motor Protection Filter

KLC Series dv/dt Output Filters

V1k provides Motor Protection by limiting voltage spikes below 1,000 volts for long lead applications(480VAC) and 1300V @ 600VAC

-

Greatly extends the life of the motor and cable

-

Specific applications can reach 3,000 feet

-

30% reduction in common mode current

The V1k is the newest generation of the KLC dv/dt output filter series. V1k filters are UL Listed and available in Open, Type 1 and Type 3R packaging configurations. The V1k supersedes the KLC product line. KLC to V1k part cross-reference is available.

Typical Problems, Superior Solutions with V1k

As Pulse Width Modulated (PWM) Drives are incorporated into various applications and processes, the increased energy savings and decreased maintenance on Drives can be offset by increases in Motor failures.

The KLC-Series V1k product family has been designed as an engineered solution for motor failures due to the reflected wave phenomenon.

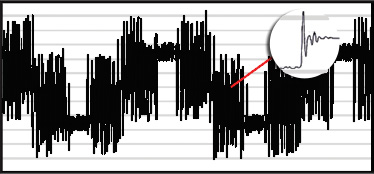

Reflective Wave Phenomenon

Voltage wave reflection is a function of the voltage rise time (dv/dt) and the length of the motor cables.

The impedance on either end of the cable run does not match, causing voltage pulses to be reflected back in the direction from which it arrived. As these reflected waves encounter other waves, their values add, causing higher peak voltage.

As wire length or carrier frequency increases, the overshoot peak voltage also increases.

Peak Voltages on a 460V system can reach 1200 to 1600V, causing rapid breakdown of motor insulation, leading to motor failure. On 575V systems, the peak voltages can easily reach 2100V. If this is left uncontrolled, insulation failure may occur.

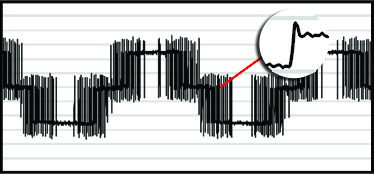

Mitigate Reflective Wave

By combining a patented dampening circuit with a low pass filter, V1k filters:

-

Increase the voltage rise time (dt out of dv/dt)

-

Prevent voltage spikes from exceeding 1,000 V (480VAC) and 1,300V @ 600VAC

-

Slow pulse transitions, reduce dv/dt

- Protect motor and cable insulation

| Voltage without V1k |

|

Voltage with V1k |

|

|

|

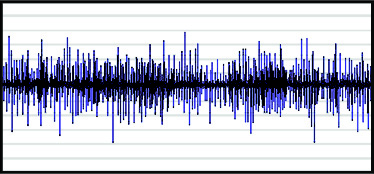

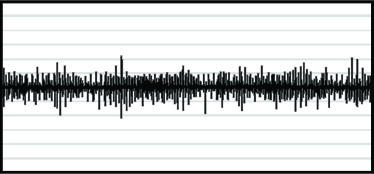

Reduces Common Mode Motor and Bearing Currents

Common Mode current, which leads to bearing pitting and bearing fluting, is reduced by a minimum of 30%. V1k filters:

-

Slow down the pulse dv/dt by a factor of 3, reducing the harmful common mode currents

-

Increase bearing life and up-time

-

Reduce common mode noise and currents

| Common Mode w/o V1k |

|

Common Mode with V1k |

|

|

|

The V1K prevents voltage spikes from exceeding 1,000 V up to 2,000 feet and limits dv/dt to less than 1,000 V/ μs. The product has been used successfully in applications up to 3,000 feet depending on cable and VFD sizes.

Multiple Motor Applications - Configuration Guidelines

-

Provide sufficient ventilation.

-

Mount the unit within ten (wire) feet from the drive.

-

Ensure the VFD's carrier frequency is set to 4 kHz or below and the operating frequency is set to 60 Hz or below.

-

Connect the VFD output leads to the A1, B1, and C1 terminations of the V1K unit. A2, B2, and C2 service the wire to the motor.

-

The length of each motor lead should be less than 500 feet and the sum total of all the leads should be less than 1,500 feet.

-

The total number of motors should be 10 or below.

V1k Specifications

-

Ratings: 2 - 750 amps; 480 Volt; 7.5 - 600 HP

-

Carrier Frequency: 1 - 12 kHz

-

Fundamental Frequency: 0 - 60 Hz (consult factory for applications over 6 kHz and/or 60 - 120 Hz fundamental if the cable lengths don't exceed 400 feet)

-

Efficiency: > 98%

-

Insulation Rating: 600V Class

-

Insulation Class: Class H (180°C) or Class R (220°C)

-

Ambient Temperature: 40° C

-

Maximum Altitude: 2,000 meters (6,000 feet)

-

Derating necessary above 2,000 meters

-

Agency Approvals: cUL, UL

-

Enclosures: Open, UL Type 1, UL Type 3R

-

Lead Length: Specific applications can reach 3,000 feet (consult factory for applications above 1,500 feet)

V1k Typical Applications:

-

Oil and Gas Pumps

-

Irrigation Fields, Farms

-

Water, Wastewater

-

HVAC

-

Pulp, Paper

V1k dv/dt Performance Guarantee

Properly sized and applied, TCI guarantees that the V1k will limit motor terminal peak input voltage to 150% of the bus voltage with a wire lead length of 1000 feet and a carrier frequency of 4 kHz. Maximum lead length and carrier frequency can vary depending on wire lead type. If a properly selected, installed, and loaded V1k filter fails to meet the guaranteed performance levels, TCI will provide the necessary components or replacement filter at no additional charge. TCI does not take responsibility for additional installation or removal costs, to include, but not limited to, replacement of third party equipment.

Minimum System Requirements for Guarantee

In order to achieve the performance levels as stated in this guarantee, the electrical system must adhere to the following: The V1K must be sized at no more than 110% of the drive output current rating. The V1K must be sized to have regular line current loading of no less than 25% of its current rating. If the load has a potential for overhauling, the drive must be equipped with braking resistors or other features limiting bus voltage to no more than the level of the peak line voltage. The V1K must be wired no more than 10 feet from the drive.